-

-

Beech hanger with pants clip, white

2024-12-25 -

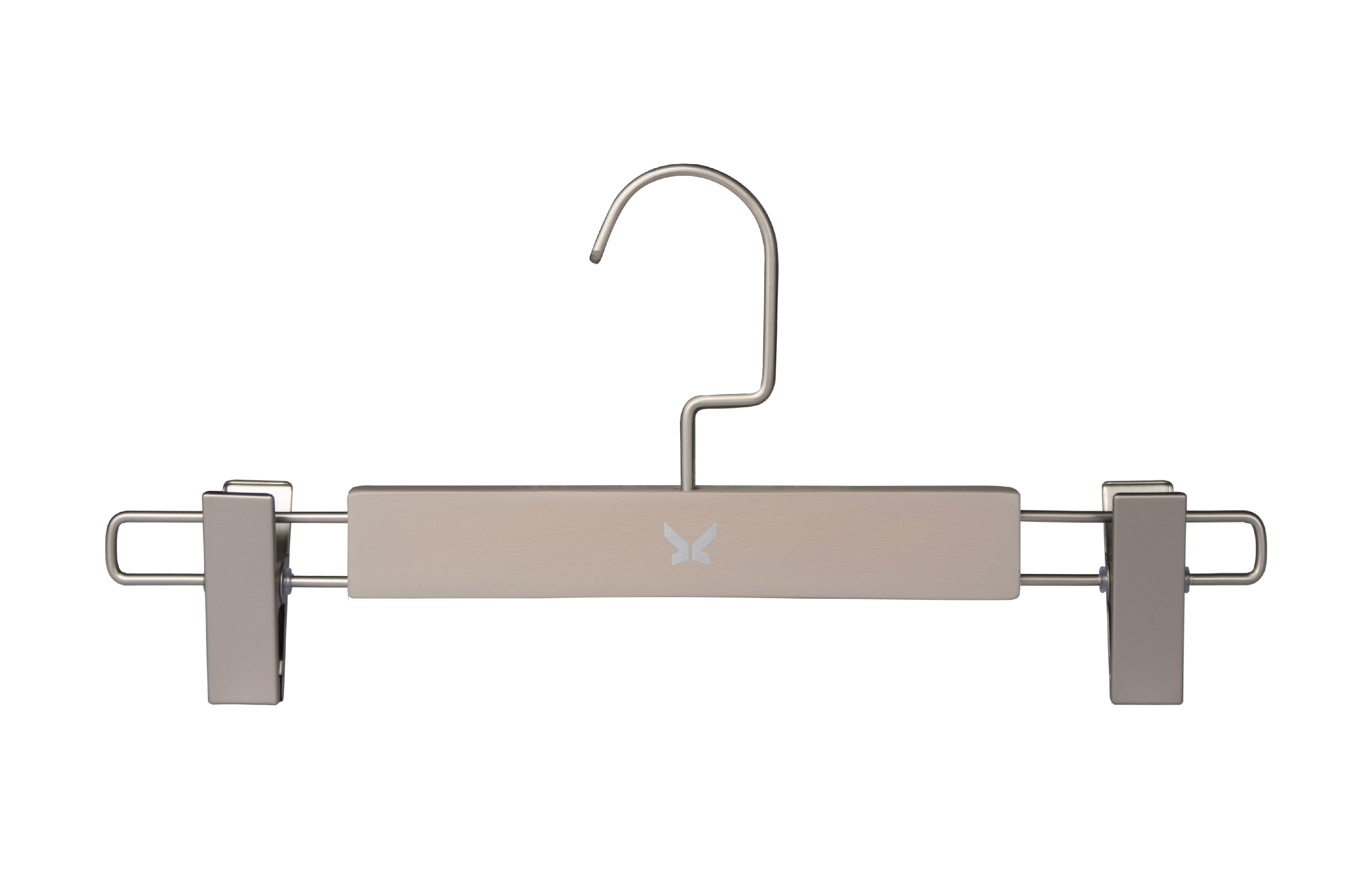

Natural beech pants rack with adjustable metal clip

2024-12-25 -

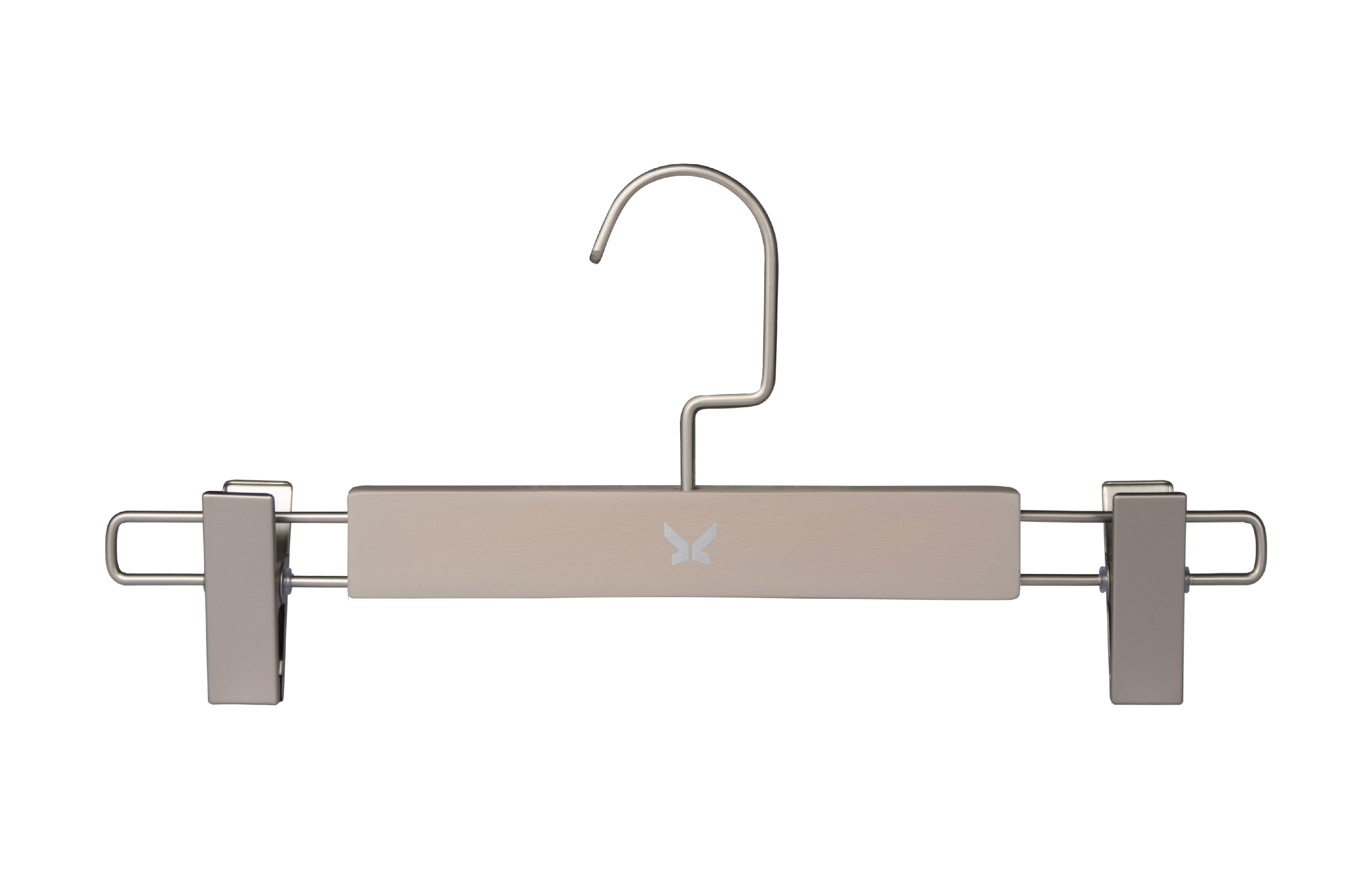

Beech wood hanger with adjustable metal clip

2024-12-25 -

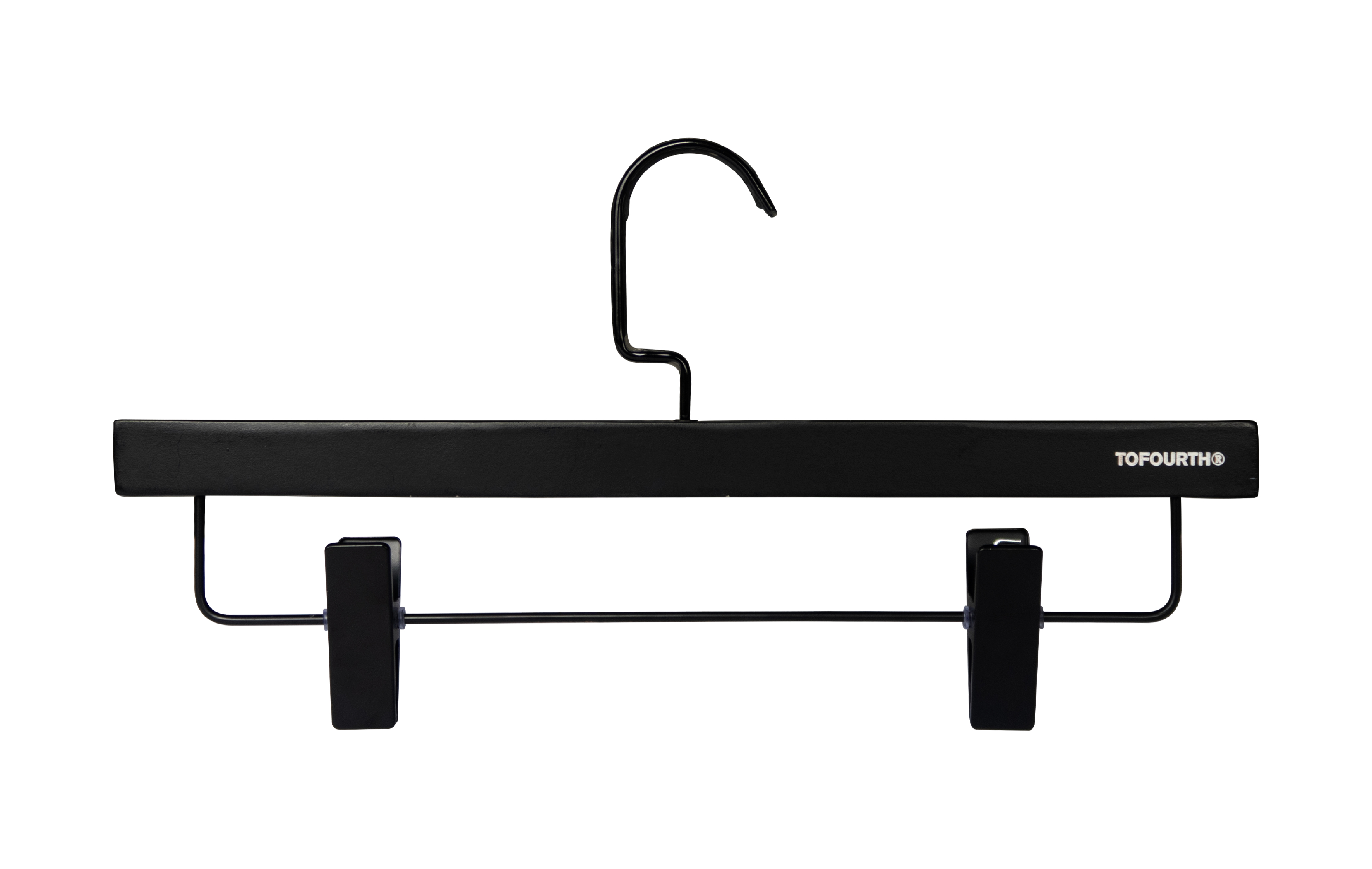

Beech trouser hanger with adjustable metal clips

2024-12-25 -

Rubber Wood Trouser Hanger with Adjustable Metal Clip

2024-12-25 -

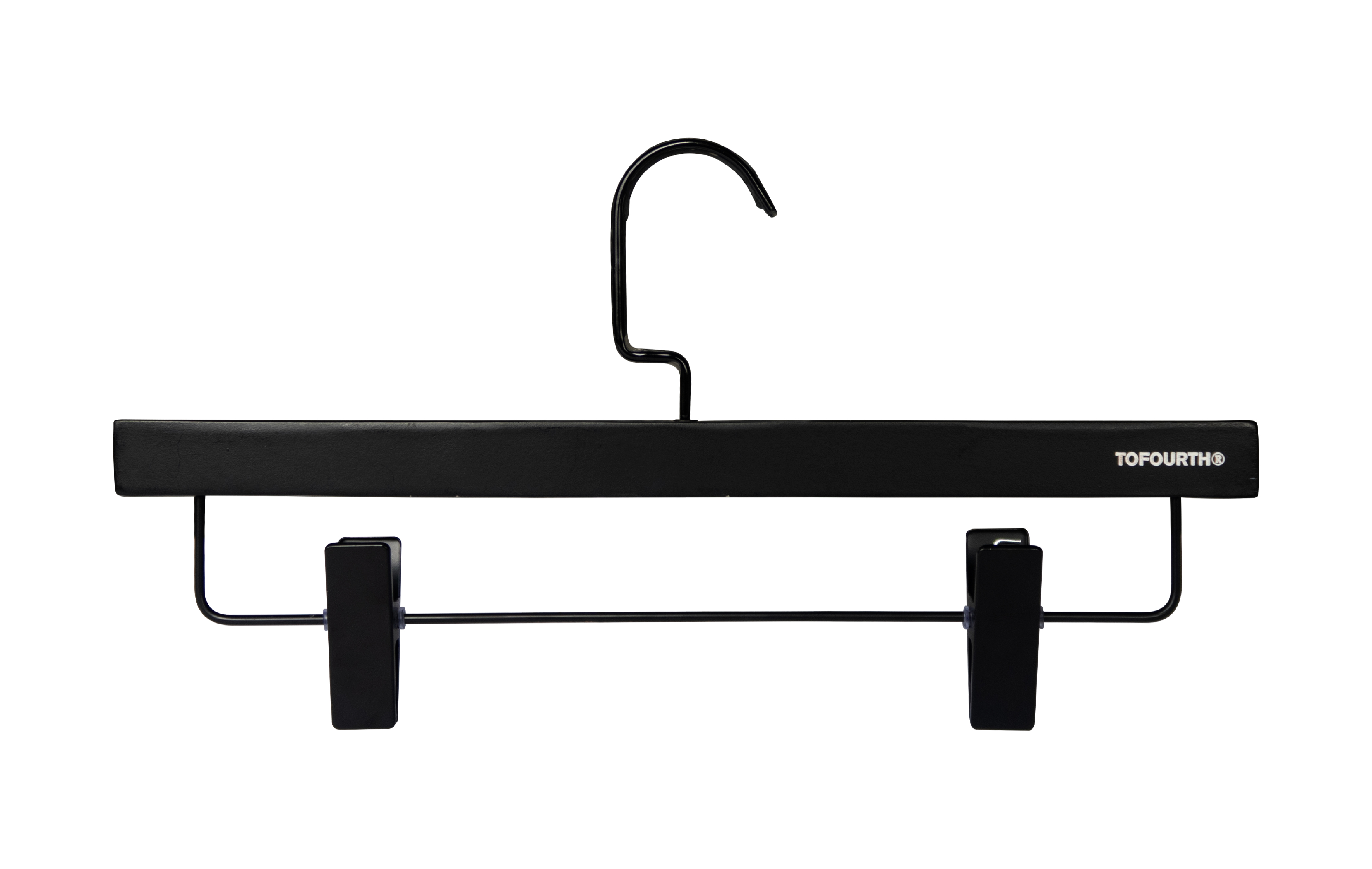

Beech trouser hanger with adjustable metal clips

2024-12-25

-

"How are wooden hangers produced?"

1,Material Selection

Selecting wood is the first step in making wooden hangers. Commonly used woods include beech, oak,birch,rubber wood,Schima,and ash, which possess high hardness and stability, making them less prone to cracking. The wood must undergo drying treatment, with moisture content controlled between 11% and 15%, to ensure stability and durability.

2,Log Processing

Subject the logs to degreasing, kiln-drying, and air-drying treatments to ensure the wood is free from wormholes, bark, and decay. During air-drying, the moisture content should be controlled below 18%, and gradually reduced to the appropriate range.

3,Scribing and Cutting

Based on the design drawings, perform scientific calculation and rational utilization of timber, then scribe and cut it into panels of required dimensions. This step requires smooth and burr-free cutting surfaces to ensure the smooth progress of subsequent processing steps.

4,Forming and Joining

Assemble the cut panels into the preliminary shape of the clothes hanger according to the design drawings. During the joining process, use specialized adhesive for fixation, and complete mortising, grooving, and other procedures through router machines or manual methods to ensure structural integrity.

5,Grinding and Polishing

After the hanger is formed, it undergoes multiple rounds of grinding to remove burrs and uneven areas, achieving a smooth and refined surface. This process typically includes coarse grinding, fine grinding, and polishing to enhance the hanger's aesthetic appeal and user comfort.

6,Spray Painting or Coating

Based on requirements, spray painting or coating treatment is applied to the hanger. The painting process involves multiple layers such as primer and topcoat sprayed through multilayer applications to enhance the adhesion, alkali resistance, and corrosion resistance of the paint surface. After coating, it is necessary to wait for the paint to dry completely.

7,Installation of Hardware Components

Install metal hooks, screws, and other hardware fittings on the clothing rack to enhance its functionality and stability. The selection and installation of hardware components must comply with the design requirements.

8,Packaging and Labeling Control

Finally, the finished garment hangers are packaged and undergo quality inspection to ensure that each product meets the required standards. During the packaging process, it is essential to protect the finished products from damage.

视频播放失败,请联系站点管理员!

COMPLETE

PROCESS

We focus on providing customers with customized commercial props solutions. Whether it is the display design that enhances the store atmosphere, the creation of DP points that attract customers' attention, or the planning of short-term but impactful pop-up stores, we can help customers realize their commercial value with professional services.